Technical Engineering

Research and Development Division

- Tooling design and development ( 3-axis milling machine, 5 axis milling machine,EDM, high-speed CNC, linear guideway)

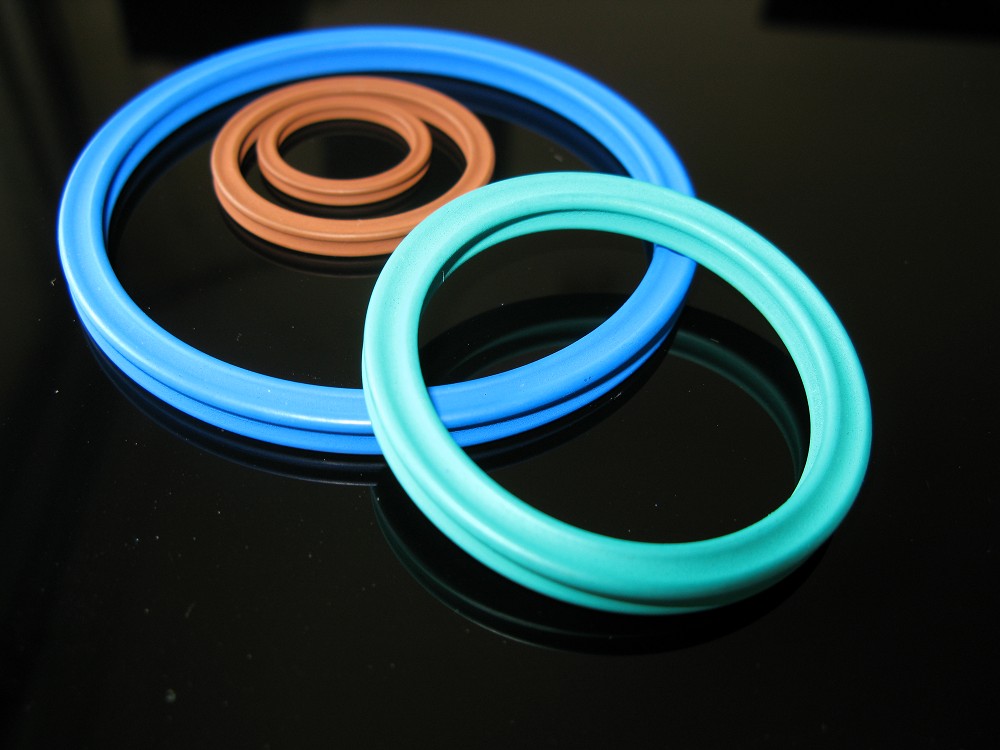

- Compound recipe design, trial mixing and preform physical properties and application testing.

- Trial molding to approve product quality (physical properties and precise dimension) and production standard setup BOM and Process (engineered through project management) standard setup for production department.

Equipments Development Division

- New equipments for client specification development, test and training.Automotive equipment development to save labor cost.

- New equipment and tool development to reduce manual operation mistake.

- High precision, High technology and Complex materials for serial production.

IT Division

Digitalize and documentarily our Know-How for application on correctly efficiently and conveniently.

R & D

We have our own in-house tooling department.

Engineering softwares, such as :

- AutoCAD, Solidworks,

- Pro-E,

- MasterCAM,

- PowerMill

are used to assist mold design.

Machinery Center

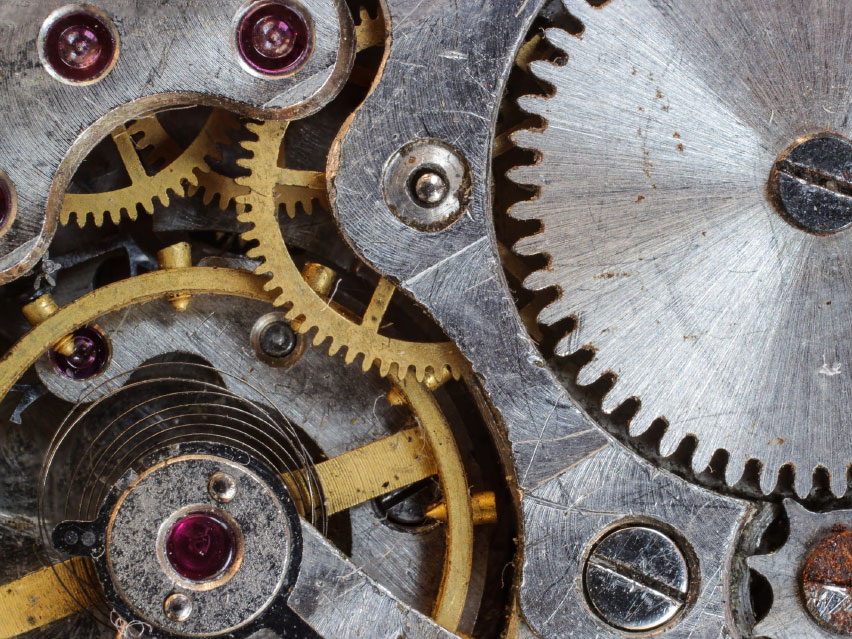

Mold Workshop:

- 3-axis milling machine x 6

- 5-axis milling machine x 1

- EDM x 2

- high-speed CNC x 2

Mold design by speciality engineers whom has well-experienced use CAD/CAM software analysis and improvement their design for abbreviate time and cost.

we set all of factors of the mold into FADP (First Article Development Process) to ensure Customer’s request.

ex: diemension precision, quality deliver and… can be guarantee 。

Assist customers to create a win-win situation

WellMore Group Inc.

Call us today

+886-2-2968-2485

or